Unveiling the Secret of Lead-Free Vacuum Sealing in Stainless Steel Insulated Cups – The Mystery of Deformation During Vacuum Sealing

Every cup has a story, and life has its warmth. Hello everyone, "Dong Dong's Cup Talk"is here again. As global markets place increasingly stringent demands on health and environmental protection, the tumbler industry continues to undergo equipment upgrades and process innovations. https://www.zhanyict.com/en/ProductsDetail-VB-10480.htmlThis is especially true in the stainless steel tumbler sector, with the vacuum sealing process being a core focus. Today, we’ll delve into this topic. To make the content easier to digest, we’ve broken it down into several standalone parts.

III. The Mystery of Deformation During Vacuum Sealing: Why Do Some Cups "Collapse"?

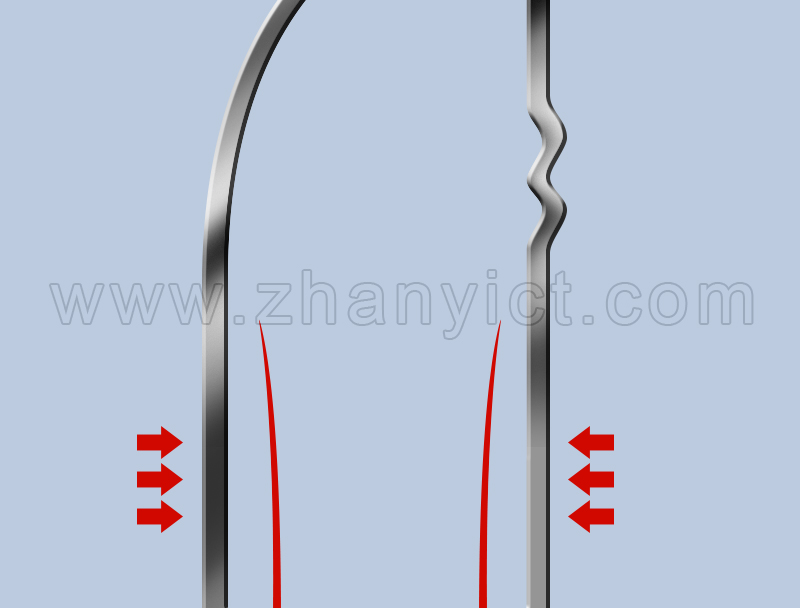

Deformation (denting, bulging, warping) of the cup body after vacuum sealing is a common production challenge.https://www.zhanyict.com/en/ProductsDetail-VB-10480.htmlIts root cause lies in the interaction of heat, force, and materials:

Core Cause: Imbalance of Internal and External Pressure & Material Yielding

The ultimate goal of vacuum sealing is to create a near-absolute vacuum within the double walls. https://www.zhanyict.com/en/ProductsDetail-VB-10480.htmlThis means the inner wall of the cup withstands enormous atmospheric pressure (approximately 1 kg per square centimeter).

When the vacuum sealing equipment stops working, atmospheric pressure instantly "crushes" down onto the cup body. If, at this moment:

The cup body material (stainless steel tube) has insufficient strength or is too thin: It cannot resist this pressure and will dent inwards (the most common type).

The cup body structure is poorly designed (e.g., a straight-walled cup has insufficient curvature at the base): Areas of stress concentration are more prone to yielding and deforming.

The temperature factor is critical: https://www.zhanyict.com/en/ProductsDetail-VB-10480.htmlDuring high-temperature sealing (especially as lead-free processes often require higher temperatures), the yield strength of stainless steel decreases. If the vacuum chamber is vented (re-introduced to air) prematurely while the cup is still hot, the softened cup body is极易 (highly susceptible to) severe, irreversible plastic deformation under the strong pressure. This is one of the primary triggers for deformation.

Which Cups Are More Prone to Deformation?

Cups made from ultra-thin-walled tubing: Products pursuing extreme lightweight (e.g., wall thickness ≤ 0.15mm) have inherently weak resistance to external pressure.

Large-capacity, large-diameter cups: https://www.zhanyict.com/en/ProductsDetail-VB-10480.htmlThe larger surface area experiences greater force, making deformation easier for the same wall thickness.

Cups with poor structural design: Models with overly flat bottoms, sidewalls lacking reinforcement ribs, or poorly smoothed curvature transitions.

Cups made from inferior materials: Cups made from non-food-grade 304/316 stainless steel or poor-quality recycled material have poor strength and ductility.

Improper process control:

Excessively high temperature or excessive duration during vacuum sealing/fusing: Unnecessarily weakens the material strength.

Venting before sufficient cooling: https://www.zhanyict.com/en/ProductsDetail-VB-10480.htmlExposing the cup body to atmospheric pressure before it has cooled and regained sufficient strength.

Unstable vacuum levels in the equipment or overly rapid venting speed: Creates a pressure shock.

There are stories in the cup, and life has warmth. Use the right cup and choose the right factory. We have dozens of patented cup and pot products and provide OEM services to the world. We have dozens of professional engineers who provide cup and pot product development services to the world. We have multiple complete current cup and pot product production lines to provide OEM services to the world. Dongguan Zhan Yi Commodity Technology Co.,Ltd. attaches great importance to contracts and quality. We welcome global merchants to conduct on-site factory inspections and in-depth cooperation.