Comprehensive Analysis of Printing Techniques in the Water Cup Industry (Comparative Study of Mainstream Printing Processes Part 1)

There's a story in every cup, warmth in every life. Hello everyone, "Dong Dong's Cup Talk" is here.

The water cup industry has evolved dramatically from its 1.0 era to the current 6.0 era, with significant transformations in functionality, design, materials, patterns, and sales approaches. Today, we'll examine the various printing techniques that enable the increasingly diverse and personalized designs seen in modern water cups. http://www.zhanyict.com/en/ProductsDetail-VB-10404.htmlGiven the depth of this topic, we'll present it in multiple installments. If you appreciate our content, don't forget to "raise your prosperous hands" and give us a like!

In water cup manufacturing, the selection of printing techniques directly impacts product aesthetics, durability, and market competitiveness. Different materials (stainless steel, plastic, glass) have distinct printing requirements, http://www.zhanyict.com/en/ProductsDetail-VB-10404.htmlwhile design complexity (single-color logos, photorealistic images, embossed textures, etc.) further influences process compatibility. This analysis systematically examines core printing technologies through four dimensions: process principles, material compatibility, 3D effect realization, and adhesion assurance.

I. Technical Characteristics and Comparative Advantages of Mainstream Printing Processes

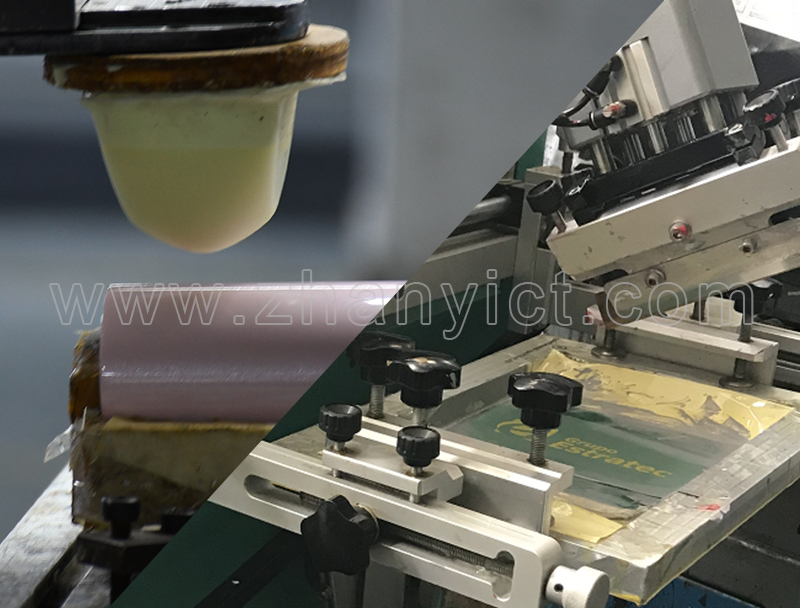

1. Screen Printing (Single-color/Multi-color)

- Principle: Transfers ink through mesh stencil openings, http://www.zhanyict.com/en/ProductsDetail-VB-10404.htmlallowing multi-color layering

- Compatible Materials: Stainless steel, glass, PP/PC plastics (requires pretreatment)

Features:

✔ Advantages:

- Thick ink layers with strong opacity

- Cost-http://www.zhanyict.com/en/ProductsDetail-VB-10404.htmleffective for single-color logos

- High color saturation achievable through multi-color registration

✖ Disadvantages:

- Poor gradient effects

- Fine details (<0.2mm lines) prone to bleeding

- Requires separate plates for curved surfaces, http://www.zhanyict.com/en/ProductsDetail-VB-10404.htmlreducing yield

2. Pad Printing (Single-color/Multi-color)

- Principle: Silicone pad picks ink from engraved plate and transfers to curved surfaces

- Compatible Materials: AS, http://www.zhanyict.com/en/ProductsDetail-VB-10404.htmlTritan plastics for irregular shapes, localized printing on stainless steel

Features:

✔ Advantages:

- Excellent adaptability to complex curves

- Ideal for irregular areas like cup rims and handles

✖ Disadvantages:

- Multi-color registration depends on equipment precision

- Low efficiency for large-area patterns

(To be continued in Part 2: Digital Printing vs. Heat Transfer Techniques)

Industry Insight:

- Screen printing remains dominant for basic logo applications (60% of mass-produced cups)

- Pad printing captures 85% http://www.zhanyict.com/en/ProductsDetail-VB-10404.htmlof irregular surface decoration market

- Emerging hybrid techniques combine both methods for complex designs

Which printing challenge are you facing? Share your questions below for customized solutions!

There are stories in the cup, and life has warmth. Use the right cup and choose the right factory. We have dozens of patented cup and pot products and provide OEM services to the world. We have dozens of professional engineers who provide cup and pot product development services to the world. We have multiple complete current cup and pot product production lines to provide OEM services to the world. Dongguan Zhan Yi Commodity Technology Co.,Ltd. attaches great importance to contracts and quality. We welcome global merchants to conduct on-site factory inspections and in-depth cooperation.